What Are Tapered Roller Bearings?

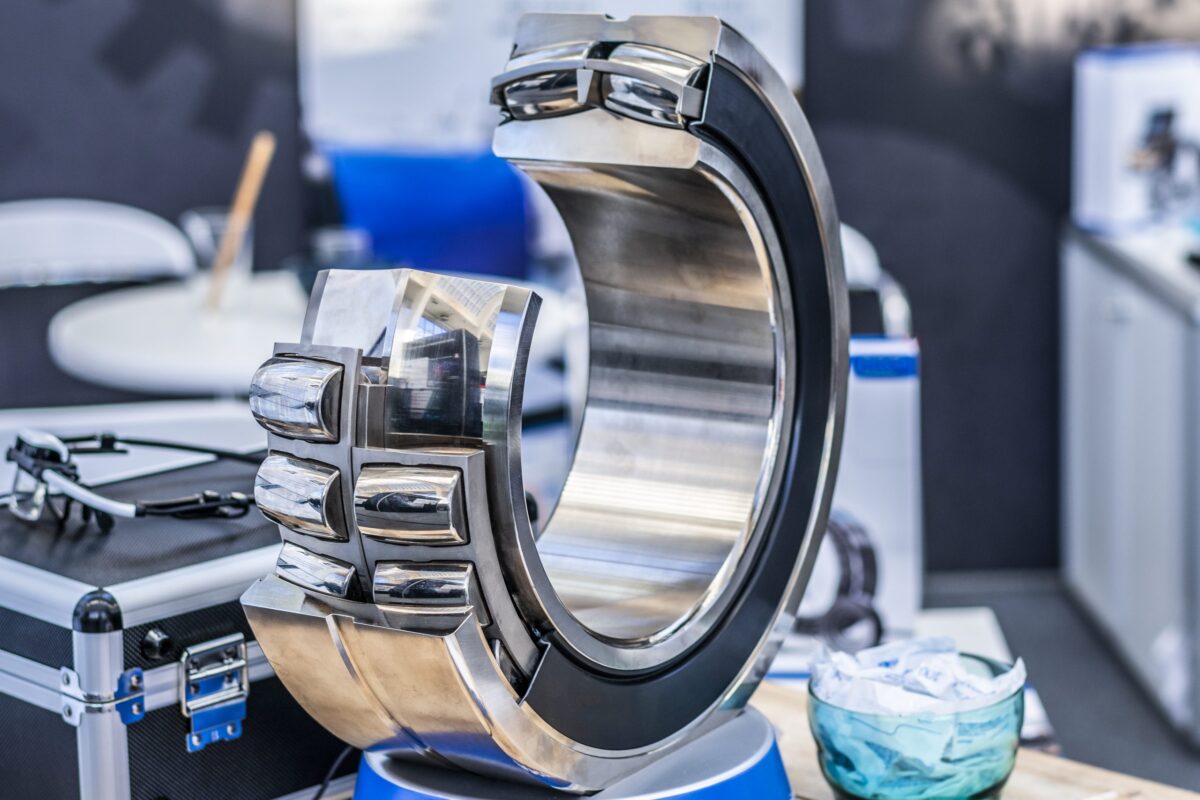

Tapered roller bearings are a specific type of bearing designed to handle both axial and radial loads. They consist of an inner ring, an outer ring, and tapered rollers, which are aligned in a way that allows them to support heavy loads and reduce friction effectively.

Applications of Tapered Roller Bearings

These bearings are widely used in various industries due to their ability to manage high loads and withstand extreme conditions. Common applications include automotive hubs, gearboxes, and machinery in industries such as mining, construction, and agriculture. Their robust design makes them ideal for heavy-duty applications where reliability is crucial.

Advantages of Using Tapered Roller Bearings

One of the primary advantages of tapered roller bearings is their load-bearing capacity. They can handle both radial and axial loads, making them versatile for various applications. Additionally, their design helps in reducing friction and wear, which extends the lifespan of the machinery they are used in. The tapered design also aids in better alignment and stability under load, ensuring smooth operation.

Maintenance and Care for Tapered Roller Bearings

Proper maintenance is essential to ensure the longevity and performance of tapered roller bearings. Regular inspection for signs of wear, lubrication to reduce friction, and ensuring correct installation are crucial steps in maintaining these bearings. It is also important to use the appropriate type of lubricant and to follow the manufacturer’s guidelines for maintenance.